What it takes to WAG!

More about Acai and crew that brings your suits to life!

About the crazy

Purple Berry Wild Dog

behind Waggery...

I found furry in 2013, and was incredibly fortunate to make amazing friends including Syber Wuff and in 2015 she brought Wild Acai into my world. The most amazing and life changing thing that's happened to me. I discovered a huge interest in how suits were made and wanted to begin building suits. So in 2017 I decided to jump into fursuit building, and sold my previous successful business of 23 years to pursue this new path. With a background of artistry and a head for engineering found this is a true passion.

My goal has been to take suits to another level, in artistry, in build quality, and in the customer experience. Nothing makes me more happy than making something that brings so much happiness and enjoyment to the owner and everyone around!

With every suit I build I'm constantly looking on how I can improve my artistry, design, and quality. This has been the most exciting and rewarding thing I've ever done in my life and every day can't wait to get to work and design, pattern and build more fuzzies! :D

Fursuit makers are some of the most sharing individuals and have been very fortunate and thankful for everyone who has contributed to my knowledge including Syber Wuff, Celar, Gabriel Felix, and many many others. I hope that the innovations that I have been developing can benefit and progress all of the makers to continue growing the quality and artistry of fursuits.

See the Critters we've made!

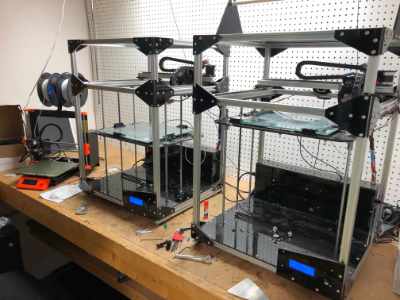

Our Studio and Equipment

We have over 2000 square feet of dedicated space for Waggery. We have an inventory of over $100k of fur, and make regular rounds of buying to try and "have it all". By having fur in stock, we can more easily match fur on existing suits, and have a wide array of choices for building new suits. This also solves delays and issues with unavailability of fur.

Six 3D printers for production of molds, eyes, teeth and other items needed in production of suits. We utilize all industrial equipment including 4 cup feed sewing machines, 5 thread serger, Walking Foot Zig Zag Cylinder Arm, and conventional presser foot machines. We get the best restuls by using the proper industrial equipment, and maximum reliability. We also have a Melco EMT 16+ Commercial Embroidery machine for paw pads, and details on bodies.

Come Join Our Family!

We're proud to say that as of end of 2022, we have completed over 100 full suits since our starting in 2018. In addition we have completed over 250 bodies, and too many pairs of paws to count. This has given us a lot of experience and refinement on how to make suits that are durable, and built efficiently. Not everything we've done is in our portfolio (wrangling up pics is hard sometimes).

Below are some group pictures taken from different cons over the years. Its SO fun to see the family grow! (some suiters are fuzzies that we've just done bodies and parts for too... but our heads are very easily recognizable!)